Telephone

Polyvinylidene fluoride (PVDF) is a versatile fluoropolymer known for its excellent chemical resistance, thermal stability, and piezoelectric properties. It's used in a variety of applications such as membranes for water purification, coatings, batteries, and medical devices.

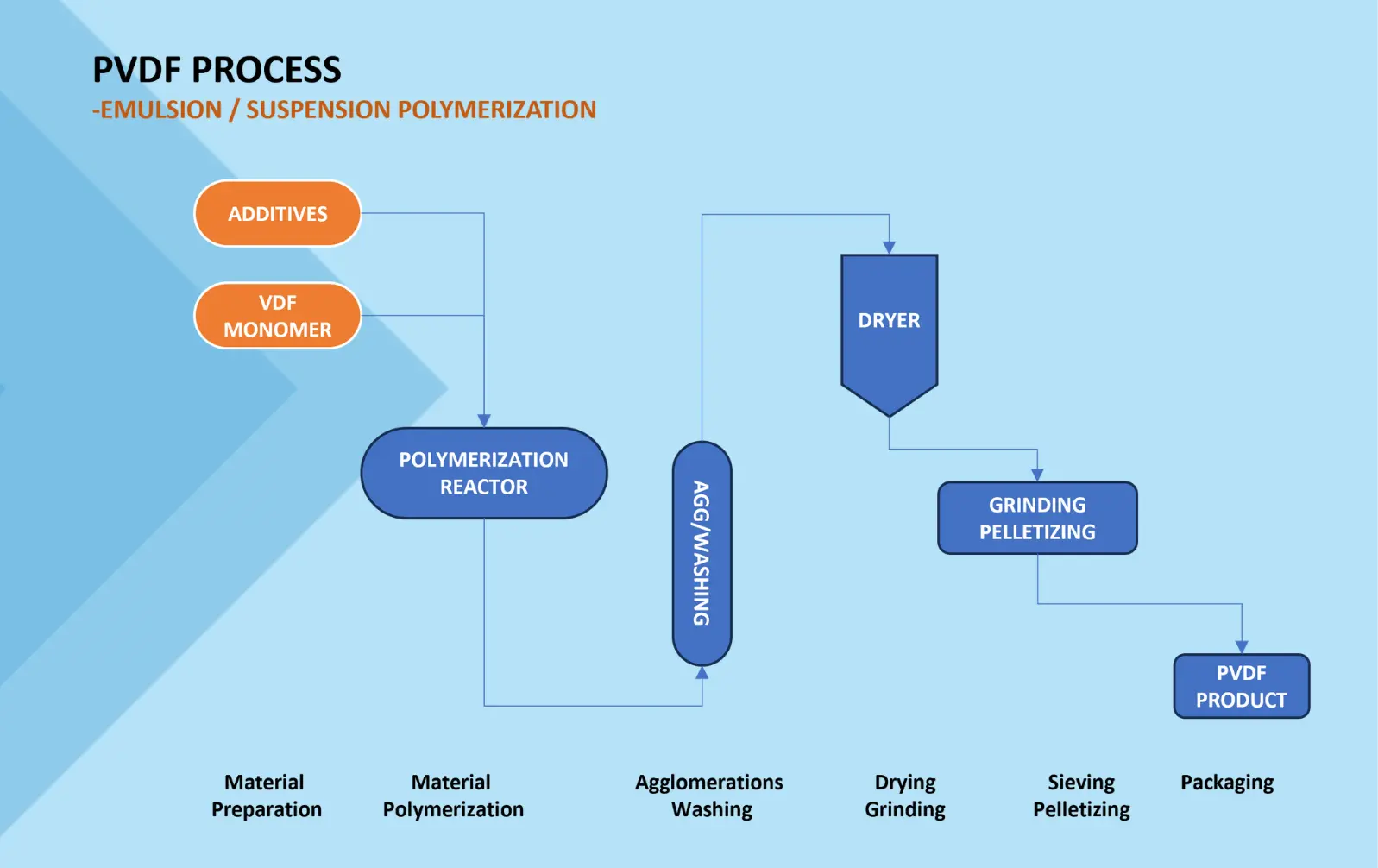

The synthesis of PVDF can be accomplished through several methods including emulsion polymerization and suspension polymerization.

Emulsion Polymerization

Emulsion polymerization involves dispersing the monomer, vinylidene fluoride (VDF), in an aqueous medium with the help of surfactants. An initiator that is soluble in water is added to start the polymerization reaction. The process typically includes the following steps:

1. Preparation of the Aqueous Medium: Water and surfactants are mixed to form a stable dispersion.

2. Monomer Addition: Vinylidene fluoride is introduced into the aqueous medium.

3. Initiation: An initiator such as a persulfate salt is added to generate free radicals that will initiate the polymerization.

4. Polymerization: The mixture is heated under controlled conditions to promote the growth of PVDF chains.

5. Work-up: After completion of the reaction, the resulting latex (PVDF particles dispersed in water) is worked up to remove unreacted monomer and other impurities.

Suspension Polymerization

In suspension polymerization, the monomer is suspended in water using mechanical agitation and dispersing agents. The process is similar but differs in the state of the monomer and the method of dispersion:

1. Preparation of the Suspension: VDF is suspended in water using mechanical stirring and dispersing aids.

2. Initiation: An oil-soluble initiator is added to the suspension.

3. Polymerization: The suspension is heated, causing the initiator to decompose and produce free radicals that initiate the polymerization.

4. Work-up: Once the polymerization is complete, the PVDF particles are isolated from the aqueous phase, washed, and dried.

Raw material | Unit Consumption (T/T) |

VDF | 1.10 T |

PURE WATER | 80 m3 |

ADDITIVE1 | 3.0 kg |

INDUSTRIAL WATER | 6 m3 |

PWOER | 2200 KWH |

STEAM | 3 T |

PURE N2 | 7 Nm3 |